Ensuring Accurate Measurements for Optimal Performance

Objective:

To provide a step-by-step guide on accurately measuring for a new or replacement driveshaft, ensuring optimal fitment and performance.

Tools Needed:

- Tape Measure

- Notepad and Pen

- Calculator

- Vehicle Lift or Jack and Jack Stands

- Safety Gear (Gloves, Goggles)

Steps to Measure Driveshaft Length:

-

Prepare the Vehicle:

- Safety First: Ensure the vehicle is parked on a flat, stable surface. Engage the parking brake.

- Lift the Vehicle: Using a vehicle lift or jack stands, raise the vehicle off the ground to provide easy access to the driveshaft area. Securely support the vehicle.

-

Identify Transmission Model and Output Shaft:

- Locate the Transmission: Identify the transmission model installed in your vehicle. The model can usually be found on a metal tag or stamped on the transmission casing.

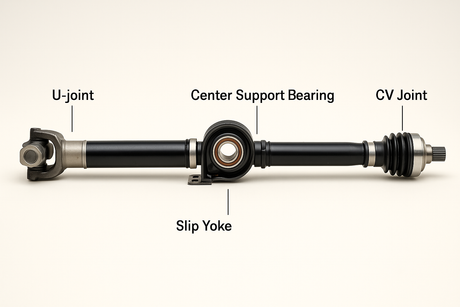

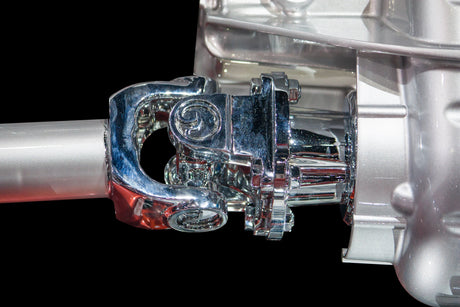

- Measure Output Shaft: Measure from the rear of the transmission housing to the centerline of the U-joint or slip yoke.

Common Transmission Models and Their Measurements:

GM (General Motors):

-

TH350 (Turbo-Hydramatic 350):

- Length: Approximately 21.75 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

-

TH400 (Turbo-Hydramatic 400):

- Length: Approximately 24.37 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

-

4L60E:

- Length: Approximately 30.75 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

Ford:

-

C4:

- Length: Approximately 20.25 inches (short version) or 27 inches (long version)

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

-

C6:

- Length: Approximately 22.5 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

-

AOD (Automatic Overdrive):

- Length: Approximately 30 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

Chrysler:

-

727 Torqueflite:

- Length: Approximately 24.5 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

-

904 Torqueflite:

- Length: Approximately 21.5 inches

- Measurement Point: From the rear of the transmission to the centerline of the U-joint.

Consideration for Accurate Measurement:

-

Measure Centerline Distance:

- From Transmission Output Shaft: Measure from the centerline of the transmission output shaft to the centerline of the U-joint cup at the differential yoke.

- Note Measurement: Record this measurement precisely. This is the total driveshaft length needed.

-

Consider Vehicle Position:

- Loaded Position: Ensure the vehicle is in its fully loaded position (with all regular weight accounted for, such as fuel and any regular cargo) when measuring to account for suspension sag and ensure accurate length.

-

Cross-Check:

- Double-Check Measurements: Repeat the measurement process to ensure accuracy. Small errors can lead to improper fitment.

Common Driveshaft Measurements:

- Transmission to Differential (One-Piece Driveshaft): Measure from the transmission output shaft to the differential yoke.

- Two-Piece Driveshafts: Measure from the transmission output shaft to the center support bearing, then from the bearing to the differential yoke.

Types of Driveshafts:

-

One-Piece Driveshaft:

- Used in vehicles with shorter wheelbases.

- Advantages: Simplicity, fewer moving parts.

-

Two-Piece Driveshaft:

- Used in vehicles with longer wheelbases.

- Advantages: Better alignment and balance, reduced vibration.

Additional Tips:

- Measure with Suspension Loaded: Always measure with the vehicle’s suspension in its loaded state to get the most accurate measurement.

- Use Suitable Tools: Ensure your tape measure is rigid enough to avoid sagging, which can cause inaccurate readings.

-

Record All Measurements: Keep a detailed record of all measurements and any

relevant observations during the process.

Troubleshooting Common Issues:

-

Vibrations:

- Balancing Issues: Ensure that the driveshaft is professionally balanced.

- Misalignment: Check the alignment of the driveshaft with the transmission and differential yokes.

- Worn U-Joints: Inspect and replace worn U-joints to prevent vibrations.

-

Noisy Operation:

- Lubrication Issues: Ensure that the slip yoke and U-joints are properly lubricated.

- Worn Components: Replace any worn or damaged components such as U-joints or carrier bearings.

-

Drive Shaft Play:

- Incorrect Length: Verify the driveshaft length; too long or too short can cause play and premature wear.

- Worn Slip Yoke: Inspect the slip yoke for wear and replace if necessary.

-

U-Joint Bind:

- Incorrect Angles: Check and correct the operating angles of the U-joints to avoid binding.

- Improper Installation: Ensure U-joints are installed correctly and not over-tightened.

Upgrade Considerations:

-

Performance Driveshafts:

- Material Upgrades: Consider upgrading to high-performance materials such as carbon fiber for reduced weight and improved strength.

- High Torque Applications: Use heavy-duty U-joints and larger diameter driveshafts for high torque and high-stress applications.

-

Slip Yoke Eliminator Kits:

- For Off-Road Vehicles: Reduce the chances of driveshaft slip yoke damage during extreme suspension articulation.

- Improved Driveshaft Angles: Maintains better driveshaft angles for lifted vehicles.

Maintenance Tips:

-

Regular Inspections:

- Check for Wear and Tear: Regularly inspect the driveshaft and associated components for signs of wear or damage.

- Lubrication: Periodically lubricate U-joints and the slip yoke to prevent premature wear.

-

Proper Cleaning:

- Remove Debris: Keep the driveshaft clean and free from debris that can cause unbalance.

- Prevent Rust: Apply anti-corrosion treatments, especially for steel driveshafts to prevent rust and corrosion.

Final Checklist Before Ordering or Fabricating Driveshaft:

- Transmission Type and Output Shaft Measurement

- Differential Yoke Centerline Measurement

- U-Joint Compatibility and Sizes

- Required Slip Yoke Type and Spline Count

- Driveshaft Material Preference (Steel vs. Aluminum)

- Total Length Measurement Confirmed in Loaded Condition

- Professional Balancing Requirement Noted

This bulletin aims to provide a comprehensive guide to ensure that every driveshaft measurement is precise, leading to optimal fit and vehicle performance. Accurate measurements and proper maintenance are key to avoiding issues and ensuring long-term reliability.

For additional assistance or clarification, consult with a professional driveshaft specialist or refer to your vehicle’s service manual. Having precise measurements and understanding the specifics of your vehicle’s drivetrain ensures that your new or replacement driveshaft will perform flawlessly.

-