Keeping classic cars on the road requires more than just passion; it demands expertise and a keen eye for detail. One crucial aspect often overlooked is the driveshaft. Expert driveshaft rebuilds are essential for maintaining the performance, safety, and longevity of older vehicles. This article takes you through the intricacies of driveshaft rebuilds, offering insights into critical parts, specifications, and some DIY tips for the dedicated car enthusiast.

1. The Crucial Role of the Driveshaft

Integral to Performance and Safety The driveshaft is responsible for transmitting torque from the transmission to the differential, which in turn drives the wheels. Over time, wear and tear can lead to imbalances, vibrations, and potential failure. Understanding the importance of a well-maintained driveshaft is crucial for any classic car owner.

2. Key Components of a Driveshaft

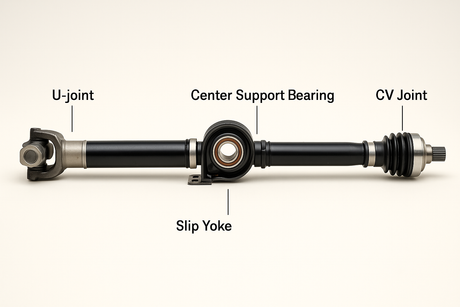

Understanding the Parts:

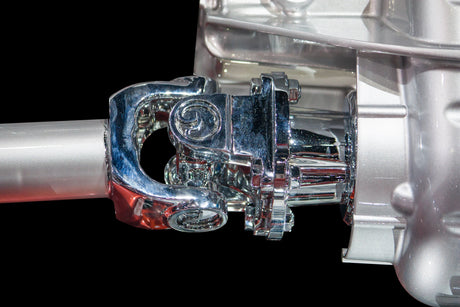

- U-Joints (Universal Joints): These allow the driveshaft to flex and articulate as the vehicle moves. Worn U-joints can lead to vibrations and noise.

- Shaft Tubing: The tubular section connecting the transmission to the differential. It needs to be perfectly balanced to avoid vibrations.

- Slip Yoke: This attaches the driveshaft to the transmission. It allows for length changes as the suspension moves.

- Flange Yoke: Connects the driveshaft to the differential.

- Center Support Bearing: Found in two-piece driveshafts, this supports the connection between the two shafts, reducing vibrations.

3. The Driveshaft Rebuilding Process

Step-by-Step Guide to Perfection:

- Inspection: Start with a detailed inspection to identify wear and damage. Look for cracks, worn U-joints, and imbalance signs.

- Disassembly: Carefully disassemble the driveshaft, removing U-joints, bearings, and yokes.

- Cleaning: Thoroughly clean all components to remove grease, grime, and rust, which can complicate the rebuild.

- Machining and Straightening: Use lathe and press to address any bends or imbalances in the shaft tubing.

- Balance Check: Before reassembly, check the balance of the shaft tubing and correct any imbalance.

- Reassembly: Install new U-joints, slip yoke, and flange yoke. For two-piece driveshafts, ensure the center support bearing is correctly installed.

- Final Balancing: Re-check the balance of the entire assembly to ensure smooth operation.

4. Essential Specs for Classic Cars

Proper Specifications Ensure Optimal Performance:

- Length: Ensure the driveshaft is the correct length for your make and model to prevent binding or excessive play.

- Diameter: The diameter affects the strength and balance. Make sure it matches OEM specs or any performance upgrades you have made.

- Material: Common materials include steel and aluminum. Steel offers durability, while aluminum is lighter but requires precise balancing.

- U-Joints Size: Ensure U-joints are the correct size. High-performance U-joints can offer enhanced durability.

5. Modern Techniques and Tools

Leveraging Technology for Precision:

- 3D Scanning: Used for capturing precise dimensions of original components.

- CNC Machining: Helps in manufacturing parts to exact specifications, ensuring proper fitment.

- Dynamic Balancing Machines: Essential for ensuring that the rebuilt driveshaft is perfectly balanced, reducing the risk of vibrations.

6. DIY Tips for Driveshaft Maintenance

For the Hands-On Enthusiast:

- Regular Inspection: Periodically check for signs of wear, such as rust or looseness in the U-joints.

- Proper Lubrication: Keep U-joints and other moving parts well-lubricated to reduce wear.

- Vibration Checks: If you feel unusual vibrations while driving, inspect the driveshaft as it might indicate an imbalance or worn part.

- Tool Kit: Ensure you have a comprehensive tool kit, including wrenches, grease guns, and a torque wrench.

- Manuals and Guides: Always refer to the vehicle's service manual for specific torque specs and assembly instructions.

Common DIY Tasks:

- U-Joint Replacement: Remove the driveshaft and use a press or specialized tool to replace worn U-joints.

- Cleaning and Painting: Clean rust from the driveshaft and apply rust-preventive paint to extend its lifespan.

- Bolt Tightening: Regularly check and tighten the bolts connecting the driveshaft to the transmission and differential to avoid loose connections.

7. Balancing Authenticity with Upgrades

Maintaining Character While Enhancing Performance:

- OEM vs. Aftermarket Parts: Deciding between using original equipment manufacturer (OEM) parts and high-quality aftermarket alternatives can impact both the authenticity and performance of your rebuild. While OEM parts preserve the original character of the vehicle, modern aftermarket components can offer improved durability and performance.

- Modern Materials: Incorporating newer materials, such as carbon fiber or upgraded alloys, can reduce weight and enhance strength without compromising the vehicle's vintage feel.

- Enhanced U-Joints: Consider using greaseable U-joints with modern sealing solutions to improve longevity and reduce maintenance intervals.

8. Finding the Right Expert for the Job

Choosing Skilled Professionals: Selecting a professional with extensive experience in classic cars and driveshaft rebuilds is crucial. Look for:

- Specialization in Classic Cars: Ensure the professional has a proven track record with classic vehicles.

- Modern Equipment: An equipped workshop with advanced tools and technology ensures precision and quality in every rebuild.

- Customer Reviews: Seek feedback from previous clients to gauge the expert's reliability and workmanship.

9. Safety Considerations

Prioritizing Safe Driving:

- Testing: After completing a driveshaft rebuild, always conduct thorough testing to ensure everything operates smoothly and safely.

- Emergency Kit: Keep emergency tools and a roadside repair kit in your vehicle to address unexpected issues.

- Regular Maintenance: Schedule regular check-ups to monitor the condition of the driveshaft and other critical components.

Conclusion

The art of the driveshaft rebuild is a meticulous process blending tradition with modern innovation. By focusing on the crucial components, leveraging advanced techniques, and adhering to proper specifications, you can ensure your classic car remains both an icon of the past and a reliable performer on today's roads. Whether entrusting an expert or handling the basics yourself, maintaining your driveshaft is a testament to your dedication as a classic car enthusiast.